1. Poor Quality or Aged Thread

Cause: Inconsistent thread thickness, insufficient tensile strength, or brittleness due to prolonged storage.

Solution:

-

Use high-quality threads (e.g., polyester or silk threads).

-

Inspect the thread for moisture damage or aging, and replace if necessary.

2.Improper Tension Adjustment

Solution:

-

Recalibrate the tension dial (start with the midpoint setting and fine-tune based on fabric type).

-

Observe the stitch formation to ensure the upper and bobbin threads interlock evenly within the fabric.

3. Needle Issues

Solution:

-

Select the appropriate needle size for the fabric (e.g., size 16 for heavy denim, size 9 for delicate silk).

-

Replace needles regularly (recommended every 8-10 hours of sewing).

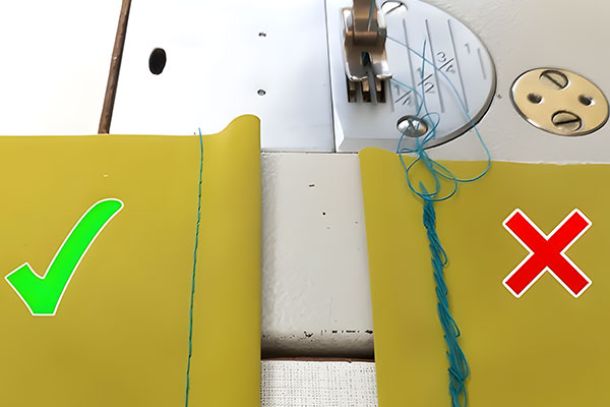

4. Incorrect Threading

Solution:

-

Re-thread the machine according to the manual, ensuring the thread passes through all guides and tension mechanisms.

-

Inspect the needle eye for burrs and replace the needle if necessary.

5. Throat Plate or Bobbin Case Wear

Solution:

-

Smooth the throat plate hole edges with fine-grit sandpaper.

-

Inspect the hook for smoothness and replace worn components if needed.

6. Excessive Sewing Speed

Solution:

-

Reduce sewing speed and avoid prolonged high-speed operation.

-

Apply silicone oil or thread lubricant (only for machines that permit lubrication).

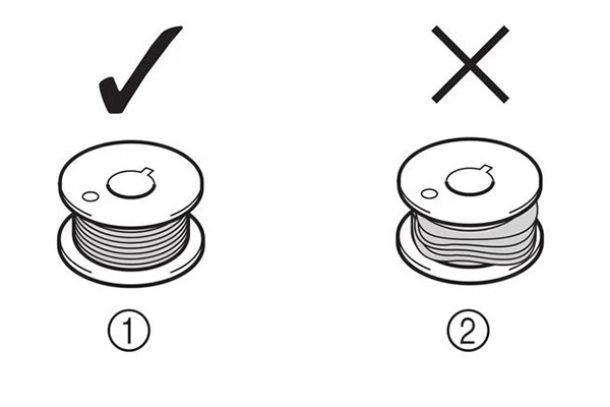

7. Bobbin Issues

Solution:

-

Rewind the bobbin evenly and ensure it fits snugly in the bobbin case.

-

Replace deformed or worn bobbins.

8. Fabric Characteristics

Solution:

-

Use stronger threads (e.g., nylon) and pair with heavier needles.

-

Apply fabric-specific lubricants to reduce friction on materials like leather.

9. Low Humidity Environment

Solution:

-

Use a humidifier to regulate humidity levels.

-

Briefly condition the thread in a humid environment (avoid over-moistening).

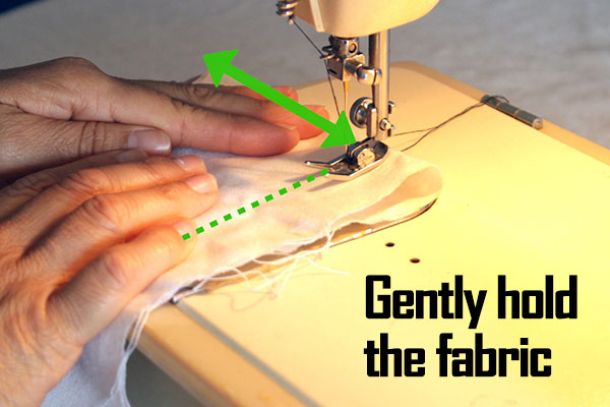

10. Improper Handling

Solution:

-

Gently guide the fabric, allowing the feed dogs to advance it naturally.

-

Manually lift the presser foot to adjust positioning at complex corners.

Troubleshooting Summary:

-

Prioritize checking the needle and threading (accounts for over 60% of thread breakage issues).

-

Test different fabrics and threads to rule out compatibility issues.

-

Gradually adjust tension, speed, and other parameters to observe improvements.

-

Perform regular machine maintenance to prevent dust buildup or component wear.

By systematically addressing these factors, most thread breakage issues can be resolved efficiently